No Die & Plate Charge

6 Days Turnaround

Free Shipping

FREE Custom Designing

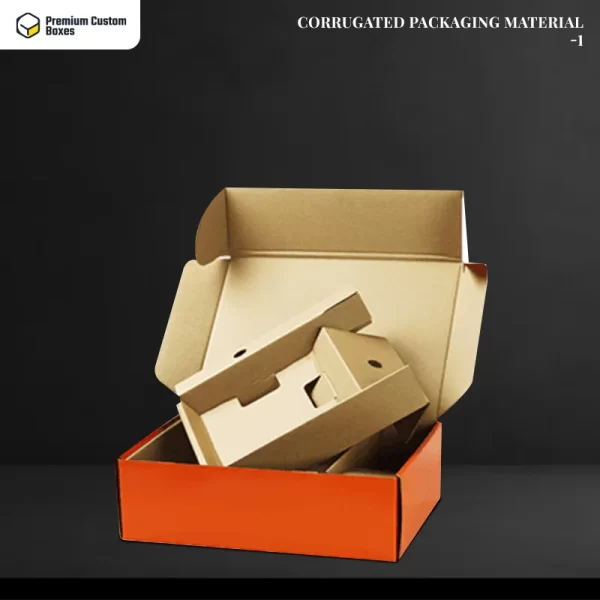

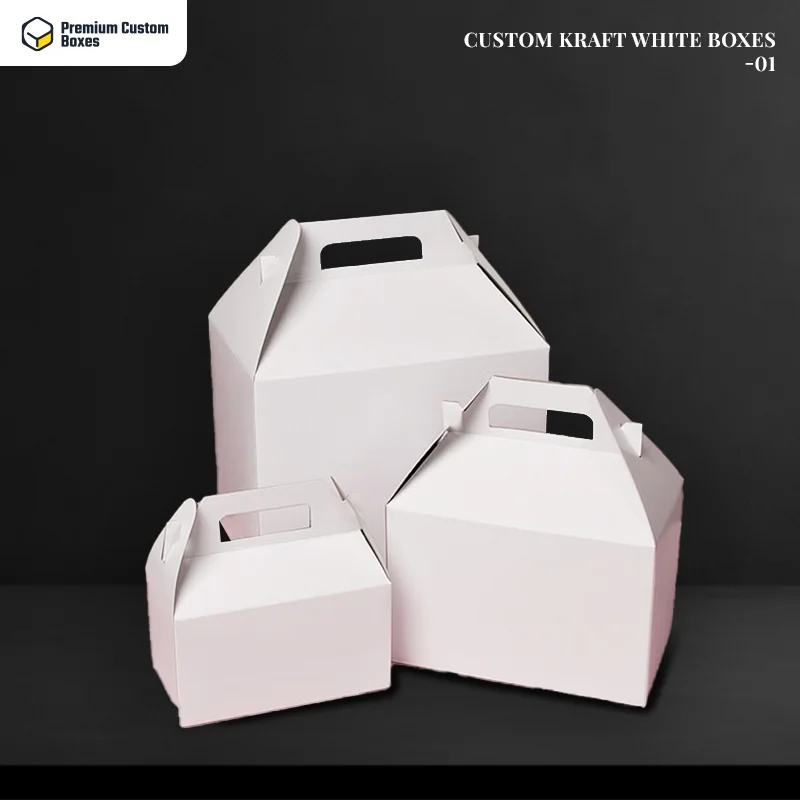

Custom Corrugated Boxes

- Walls types for durability

- Material & Flute Selection

- High-tech printing

- Smooth Finishing

Request Custom Quote

Customer Reviews

Reviews

Great company to work with... my boxes arrived safely.

Excellent product quality and fast delivery. Highly recommended!

Good value for money. The product meets all my expectations.

Corrugated boxes are a guaranteed and reliable packaging solution that provides extra security to your products during storage and shipping. These boxes are highly durable and add a protective layer to the products, making them a must-have for every industry that deals with heavy goods and stores or ships items in bulk.

PremimCustomBoxes has a wide collection of sturdier corrugated boxes at wholesale to satisfy various industries’ packing and shipping needs. These boxes withstand high pressure during storage and delivery helping you to fulfil or deliver your order safely and securely.

What is Corrugated Packaging Used For?

Corrugated boxes are widely used to transit products from one place to another, which means these boxes are highly preferable or versatile for the packaging of every product that requires reliable or studier packaging, with no specific industry usage or purposes.

Due to their protection and functional features such as withstanding high pressure and absorbing shock during delivery, corrugated shipping boxes provide massive protection to products inside, preventing them from damage or decay or ensuring safe delivery.

Where are Corrugated Boxes Used?

Offering many safety features during delivery, corrugated boxes become the first pick-up of every industry when it comes to shipping heavy items and products in bulk. With the increasing demand, corrugated packaging boxes reach 47 Billion USD in 2024, and the a possibility they may hit 52 Billion USD in 2029, with a volume of 31 million tons, only in the USA.

With this demanding growth, you may think where are corrugated boxes used? So, corrugated packaging or shipping boxes are adaptable across many industries including:

- Pharmaceutical Industries

- Retail Products Packaging

- Food & beverage Packaging

- E-commerce Packaging

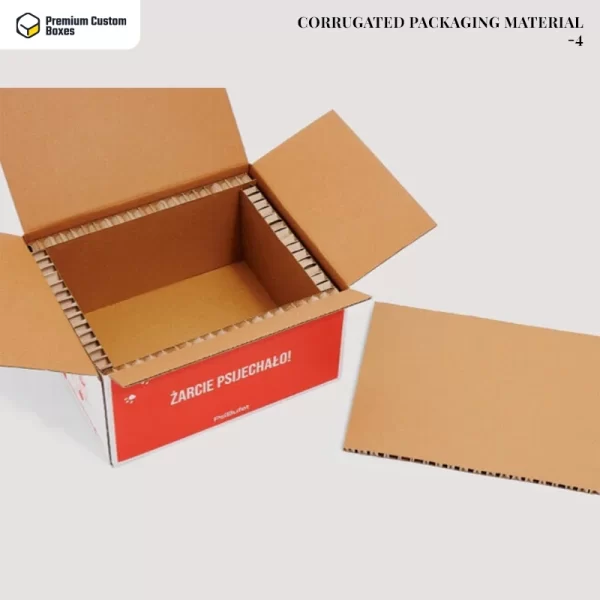

Corrugated Boxes Classification by Walls Thickness

Perfect for packaging or shipping purposes, these custom made corrugated boxes are further classified into walls to fulfil different industries’ needs. These boxes feature a unique and flat structural formation but still provide huge protection. Corrugated shipping boxes are classified as:

| Classifications | Description |

| Single Wall | Single wall corrugated boxes have one layer of corrugated fluting, that sandwiches between two liner boards, ideal for packing lightweight products. |

| Double Wall | It features two layers of corrugated fluting, placed between three linerboards, suitable for small electronic appliances. |

| Triple Wall | Triples-wall corrugated boxes are more durable than single or double-wall boxes because it has three layers of corrugated fluting medium between four-liner boards, best for packaging automotive or machinery parts. |

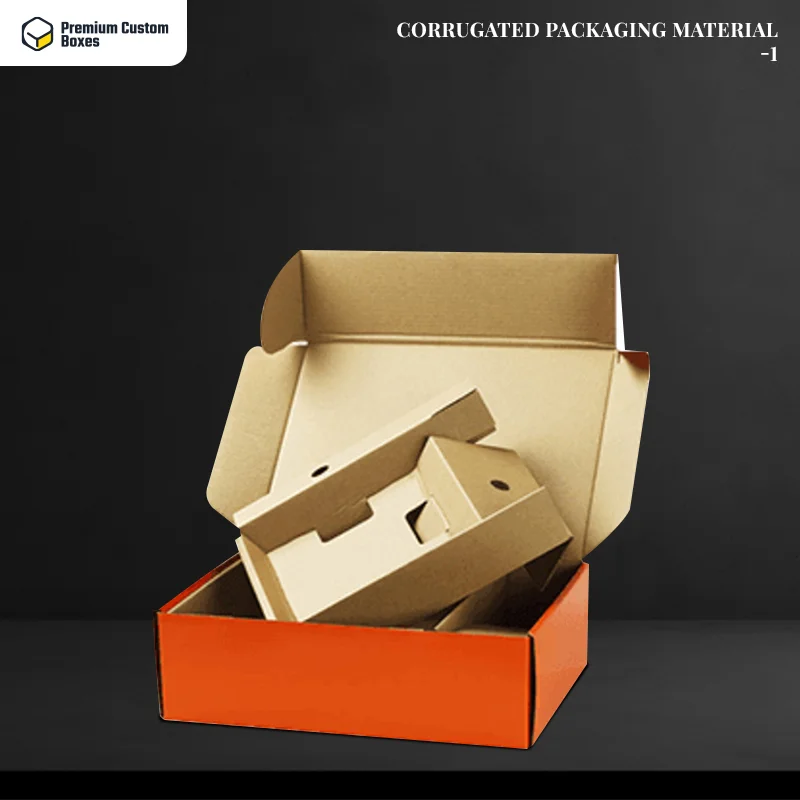

Styles Of Corrugated Packaging Boxes

The increasing demand for corrugated packaging boxes in the market is combined with current market packaging trends that make them ideal in every packaging aspect including, durability, performance and appearance. Here are some of the types of corrugated packaging boxes:

- Tab Lock Roll End

- Roll End Tuck Top

- One Piece Folder Box

- Tuck Top Auto Bottom

- Half Slotted Container (HSC Box)

Manufacturing Process Of Corrugated Boxes

Corrugated shipping boxes are the popular packaging solution, so it is important to know the complete manufacturing process:

Paper Making – Step 1:

In the manufacturing of corrugated boxes, the first step is making or selecting the paper, which is used to create outer layers. Commonly used outer liners are:

- Kraft Paper Liners

- Test Paper Liner

Flute Making – Step 2:

The next step is flute making, flute provides packaging strength and adds resistive qualities to make packaging more durable. The use of a flute depends upon the product weight that is packed in boxes. Here are different flute variations:

| Flute Type | Thickness |

| A-Flute | 1/4” thick |

| B-Flute | 1/8” thick |

| C-Flute | 3/16” thick |

| E-Flute | 1/16” thick |

| F-Flute | 1/32” thick |

Combine Paper & Flute – Step 3

After creating or selecting paper or flyte, the next step is to combine them, this step is quite easy or simple because the combining process is done by a corrugated machine.

Cutting & Folding – Step 4

In this process die-cut machine is much to cut or fold the rectangular packaging boxes into various shapes or dimensions to create complete packaging. Here, you can cut the boxes with your desired style or dimensions such as:

- Square Corrugated Boxes

- Rectangular Corrugated Boxes

Adding Insert – Step 5:

Corrugated boxes with dividers or inserts make the packaging more secure, these dividers are beneficial to add additional things to your packaging such as business cards. Moreover, custom corrugated boxes with inserts help to keep the products organised.

Printing & Labeling – Step 6:

Printing or labelling is the essential detail on packaging boxes that can’t be overlooked. A well-printed corrugated box with the brand logo, name or other essential information, builds customer trust and shows brand professionalism. We offer various printing options including:

- Offset printing

- Screen Printing

- Digital Printing

- Flexography

Why Choose PCB?

PremiumCustomBoxes, a top-rated corrugated packaging boxes supplier stocked a wide catalogue of corrugated boxes in terms of durability and appearance. We provide sturdier corrugated boxes at wholesale with flawless customisation options, ensuring to satisfy different business packaging needs, Key advantages to working with us:

- Quality Assurance

- Flawless Personalisations

- Wholesale Prices

- Free Design Assistance

- No Hidden Charges

- 24/7 Customers Support

- Fast & Free Shipping

Give your products guaranteed packaging and stand out from your competitors with custom-printed corrugated boxes. Order now and enjoy free delivery.

Q: Do I have to provide the design?

Customers need to provide the artwork or illustration of their company and, we will provide free design assistance to every customer.

Q: Can I get a Quotation for my boxes?

You can get a free quotation for your brand. You have to submit the dimensions, quantity, and other specifications regarding your order and, we will create packaging solutions according to your preferences.

Q: What is the shipping cost of custom boxes?

There is no shipping cost for the entire North America. You can get your order to your doorstep without paying extra shipping charges.

Q: What does Sample charges cost me?

Free samples are available at the order of $4000. The cost of a generic one is $9. The sample charges for every unique design are different. We have to put the setup from scratch for every unique product. So the sample charges are higher for the different designs as compared to the generic ones.

Q: What is the minimum order quantity?

We provide not less than 100 boxes to the customers.

Q: What color techniques do you use for custom boxes?

We use CMYK and PMS for printing. CMYK is best for white backgrounds and the Pantone matching system is the standard used worldwide.

Q: Is corrugated cardboard expensive?

No, this is highly affordable. Not only corrugated, but other paper-based materials are highly cost-effective.

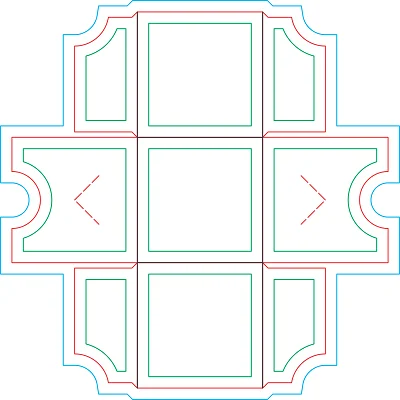

Artwork Preparation Guide

Preparing artwork for various purposes, whether it's for print, digital media, or other applications, requires attention to detail and adherence to specific guidelines. Here is a general artwork preparation guide that you can follow:

Cutting Line (Red Lines):

Indicates the cut at its final size.Important artwork and text should be placed at least 0.125 inches inside of the cutting line.

Bleed Area (Blue Lines)

Indicates where the bleed line is located. Any artwork which goes to the cutting line should be extended to the bleed line to get a seamless print.

Safe Area (Green Lines):

Indicates where artwork and text should safely be placed inside. As a industry standard, all artwork should at least be placed 0.125 inches away from the cutting lines unless your design in intentional.

Perforation Lines (Red Lines)

Perforation line refers to paper that is punched with very small holes to allow the paper to be torn and folded easily.

Creasing Line (Black Lines)

Indicated where the product is to be folded.

01

Choose Your Box

Start by browsing our extensive range of box styles and designs. Whether you're in the market for something simple and classic or intricate and bespoke, we've got a multitude of options to suit your needs.

02

Customize the Design

Once you've chosen a box style, it's time to make it uniquely yours. Upload your design or collaborate with our in-house design team to craft a packaging solution that resonates with your brand's aesthetic and vision.

03

Select Materials and Finishes

Our platform allows you to pick from a variety of materials, be it eco-friendly options, premium finishes, or durable structures. Enhance the tactile experience with finishes like matte, gloss, embossing, or specialty textures.

04

Review and Approve

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

05

Production Begins

Once you've approved the design, our team gets to work. With state-of-the-art machinery and a dedicated workforce, we ensure that each box is crafted to perfection, adhering to the highest quality standards.

06

Shipment and Delivery

With our efficient logistics network, we guarantee timely deliveries. As your boxes are packed and prepared for shipment, we'll provide tracking details to keep you informed every step of the way. Sit back and wait for your premium packaging to arrive at your doorstep.

Cardboard

Corrugated

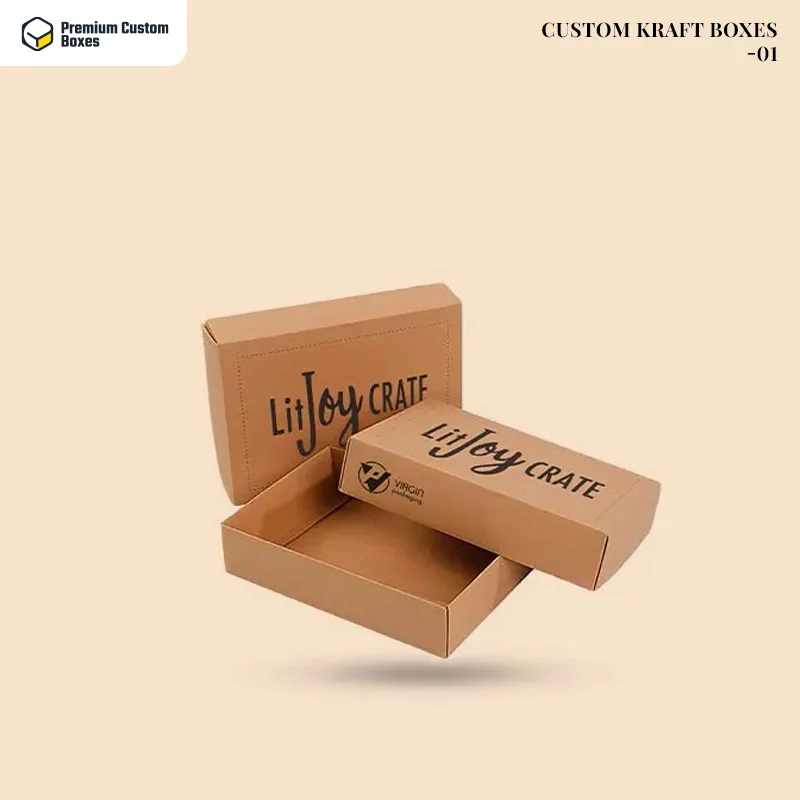

Kraft

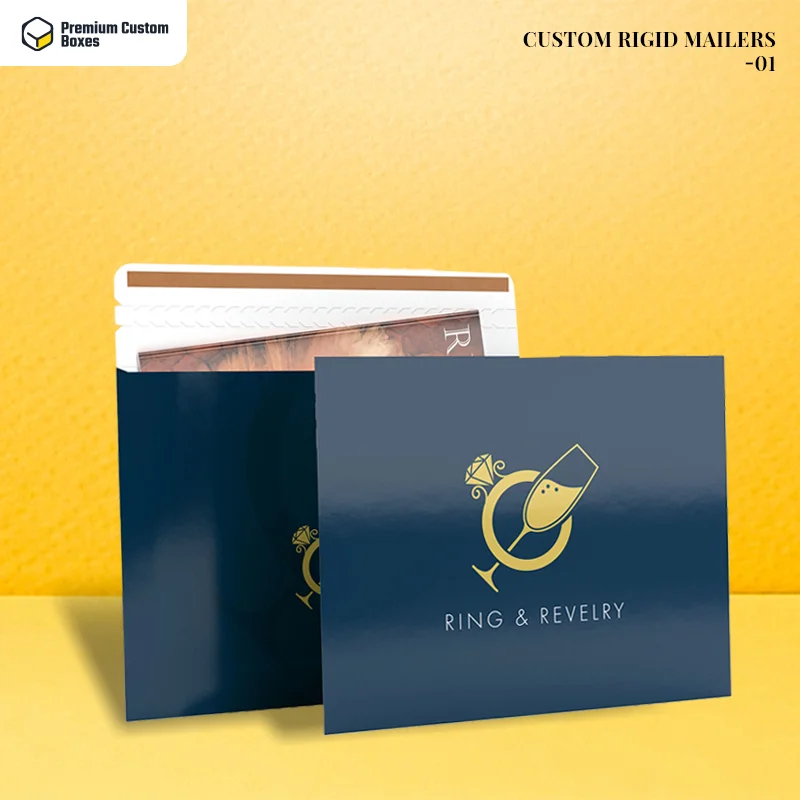

Rigid

Anti Scratch Lamination

Aqueous Coating

Lamination

Silk Lamination Cards

Soft Touch Coating

Spot UV

Gloss Lamination

Gloss Varnish

Matt Lamination

Matt Varnish

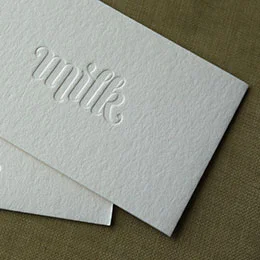

Debossing

Embossing

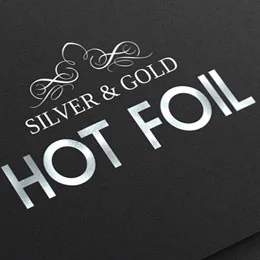

Foil stamping

Window Patching

Contact Our Customer Care Service

Are you looking forward to investing in our brand but have several concerns? Do you have ambiguity about our custom box services? If yes then you can contact our customer care representative and get all your queries answered in less than a day. Our diligent team is available for your service all around the clock. You can simply fill in the form on the website, email us on the provided email, or you can directly call us at the given number.

Get a Quote Call Us !