3000+ Satisfied Clients Worldwide

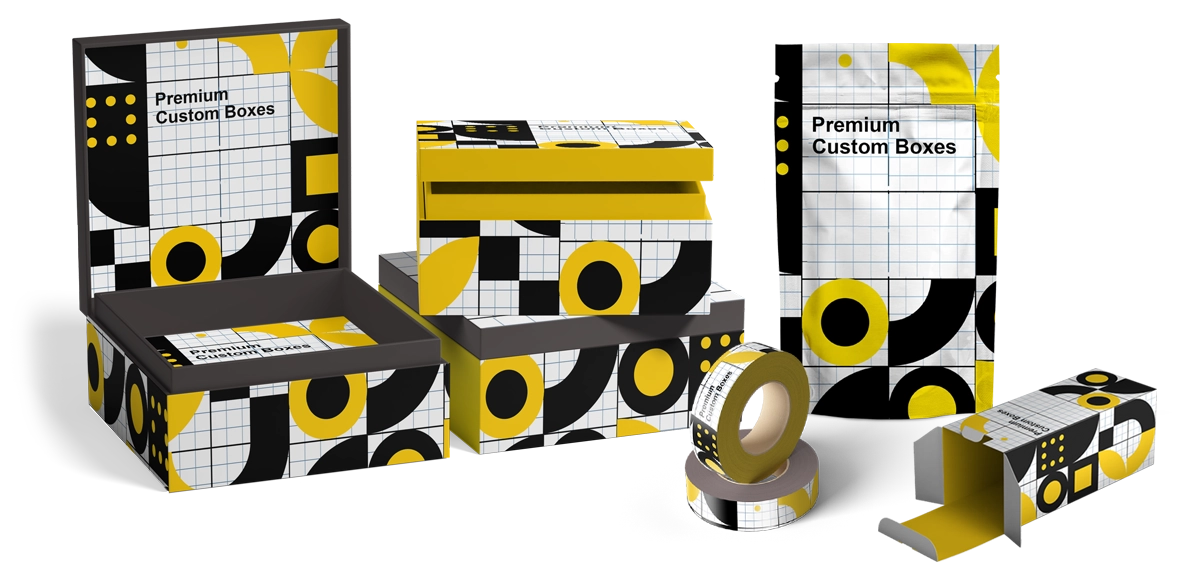

Tell An Exceptional Brand Story With Custom Printed Boxes

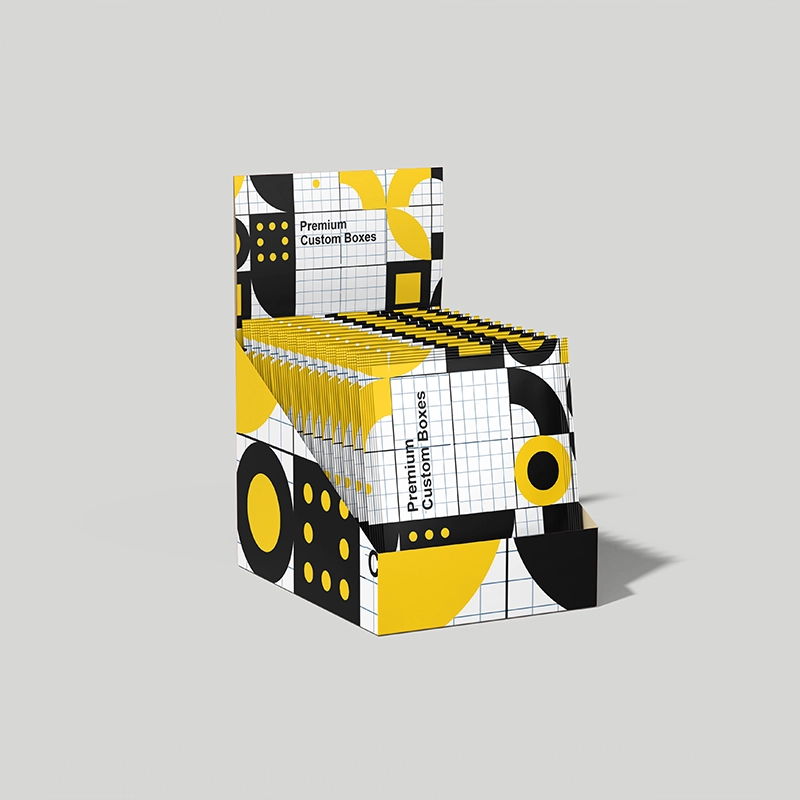

Our Process

No Die & Plate Charge

6 Days Turnaround

FREE Shipping

FREE Custom Designing

The custom boxes market has been expanding to a noticeable level. From the perspective of protecting the product to the presentation, these boxes have come up with a solution for all. Whether you want to give a vintage look to classic Britain or you are looking to merge your product in the modern surroundings, custom boxes in the UK will give you all the options.

These boxes are carefully manufactured considering the market trend and your product requirements. Aside from this, the sustainable aspect of packaging material is also considered so that your brand can show its values toward climate consciousness.

We have an extensive range of packaging that includes custom boxes for shipping to retail packaging. At us brands have the freedom to choose each and every aspect of the packaging for a better presentation and protection that fully aligns with their theme.

Why Do Brands Use Custom Boxes?

We all know that market competition is quite high, and brands have to leave no stone unturned to show the customer they are the best. Aside from competition, there are several other major reasons that make brands invest in branded custom boxes.

Supply Chain Efficiency

If a brand is using uncategorized packaging, it may have to face inefficiencies in stacking and shipping. Customised packaging is designed to match product dimensions perfectly and helps in:

- Reducing void fills

- Lower freight cost

- Minimise warehouse space usage

Custom box packaging is also crucial for brands dealing with bulk shipments. This is because in bulk shipment, small improvements in efficiency can lead to noticeable and long-term cost savings.

Compliance with Regulations

Several industries require packaging that meets strict safety and labelling standards. A generic packaging does not help in compliance and may lead to penalties. Custom boxes for products allow brands to print:

- Require certifications

- Barcodes

- Product information

- Expiry date

- Handling instructions

This ensures a smooth regulatory approval and also helps brands in international trade readiness.

Product Differentiation In Automation

We all know that modern warehouses rely heavily on automated storing and scanning systems. Standardised packaging will slow down this process, as there are no barcodes or QR codes to scan the boxes. But when you opt for a custom box, you get sufficient space to print scannable codes and machine-ready information. This ensures a seamless integration with robotics and AI-driven logistics. Brands easily make product differentiation and speed up their supply chain.

Sustainability Requirements

Brands are facing the growing pressure to adopt sustainable materials for custom boxes and packaging. Regulatory authorities and climate-conscious individuals are making it inevitable to use sustainable materials to manufacture boxes. A standard packaging may not have these qualities. When you opt for a personally designed box, you can easily comply with green initiatives.

Shelf-Ready Packaging Demands

Retailers prefer packaging that can be directly placed on shelves without extra handling. Plain packaging makes it difficult to present the product on shelves. To categorise the products, human labour is required, which will increase the cost and delay the work. A printed box customised to your brand’s theme is way easier to categorise. These boxes also contain easy-open perforations and display windows that make it easy to access and compartmentalise the product. This saves retailers’ costs and ensures your brand gets the better shelf placement.

What Material Is Used For Customized Packaging?

To ensure the sustainability of the packaging boxes, paper-based material is used. Our custom boxes wholesale material is sturdy and gives sufficient protection to the packed items. Moreover, we only use food-grade packaging material. The main purpose of boxes is to protect the product, and this protection relies hugely on the quality of materials. We have different varieties of paper-based material that differ from each other due to coatings and GSM. Those materials are:

- Kraft

- Cardboard

- Corrugation

- Rigid

We offer holistic custom packaging solutions by providing brands with a variety of paper-based materials. You can select the material thickness and coatings options considering the specific demands of your products.

Professional Die Cutting Services

We are giving professional custom packaging boxes in the UK with perfect dimensions and sizes. Our advanced die-cutting machines give precise die lines that allow us to give impeccable boxes. You can select any of the complex packaging styles, and we will ensure the exact box without any flaws.

The automated die-cutting process is efficient and ensures a short turnaround time. Whether you are looking for small custom boxes for your brand or you need large-sized boxes for bulk products, we have got you covered. The process of die cutting can be done either before or after the printing. The design complexity and the extent of accuracy decide whether we can do die cutting before or after the printing.

Custom Printing Processes

The main goal of customisation is to get printed custom boxes. These boxes are adorned with the logo of your company to give them an identity of your brand. You just have to give us your design specifications, and we will create the exact design as you desired. If you have not finalised a design, you can get a free consultation with our designers. For custom boxes with logos, we use the following processes:

- Offset printing

- Screen printing

- Digital printing

- Flexography

- Gravure printing

All the printing processes are highly efficient. The selection of printing methods relies on several factors, such as:

- Quantity of boxes

- Design complexity

- Extent of accuracy

- Budget

- Required texture

For instance, if you need custom packaging for a small business in the UK, then we use digital or screen printing. This is because both processes are ideal for small orders. We use several inks as well that give vibrant designs and an impeccable look to the boxes.

- Soy-based inks

- Water-based inks

- Petroleum inks

- PMS metallic

- UV inks

Protective Coatings

No matter how durable the material we are using, the liability of paper-based material for moisture damage can never be neglected. As an experienced custom packaging supplier, we apply coatings on the boxes that enhance the durability and make the paper-based material resistant to moisture. Coatings do several things to your packaging boxes:

- Prevent scratches and scuffs

- Protect from fingerprints

- Give a professional look

- Enhance moisture resistance

- Pop out artwork

- Enhance the legibility of typography

- Protect the printed design from fading

Our company has an extensive range of coatings that give an impeccable look to the boxes.

Varnishes

Varnishes are coating agents used to finish packaging surfaces so as to make them tougher and more beautiful. They are used to ward against scratches, dirt, and fingerprints whilst enhancing the vibrancy of colours. When it comes to business, varnish variations are used as a way of differentiating products and feel. They are available in various finishes, all of which give the option of providing different optical and textural effects that enhance brand visibility.

Laminations

Laminations are thinner protective layers on the packaging to make it stronger and tougher. They protect prints against scratches, moisture and fading. Laminations elevate the feel of the packaging tactually and possess a lavish touch. Companies employ them to prolong the life of graphics and give the business a professional look, which builds confidence in customers.

In varnishes and laminations, we have the following sub-types:

Gloss coatings

Gloss coatings give a high gloss to the surface that increases colour intensity and makes the box stand out. It forms a reflective surface which draws the attention of customers on the shelves. The gloss coatings enhance the graphics on packaging with a high degree of clarity and vivid colours. They have a common use in retail products that aim to get the attention of the customers.

Matte coatings

Matte coatings are a non-reflective coating that gives a soft, non-reflective finish, which exudes a muted elegance. It provides a silky surface which diminishes glare and improves legibility of print. Matte coatings are perfect on luxurious packaging where subtle polish is desirable. Their durability goes hand-in-hand with style, so that they have a professional and modern look.

Silk-Screen coatings

Silk screen coatings are applied where a screen is used to enable coating of an area at a time. It has depth and texture by putting an extra emphasis on logos or patterns. The slightly elevated tactile texture creates distinctiveness and high-end touch. Silk screen coatings are mostly employed by brands when it is highly important to have differentiating packaging.

Aqueous coatings

Aqueous coatings are non-toxic and water-based and are safe for food packages. It dries fast and gives a protective coating, which does not get smudgy or scratch easily. The result can be matte or glossy at the discretion of the brand. To increase packaging sustainability and support sustainable packaging, aqueous coatings are used.

UV coatings

UV coatings are dried in an instant using ultraviolet light, which yields a highly durable finish. It intensifies colour clarity and has a dramatic sheen. UV coatings also offer resistance to wear and hence could be used when there is a lot of rough handling. They can be used on a spot or full coverage basis to accentuate design elements or an entire surface.

Functional And Decorative Add-Ons

Add-ons are one of the core elements of the packaging that help in giving your product a luxurious look. If you want to make customers loyal to your brand, then you must make your product presentation distinct. We have a huge variety of add-on options that enhance the functionality as well as aesthetics of your packaging, such as:

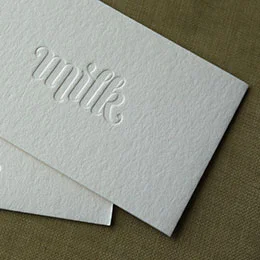

Embossing

Embossing involves the placement of a raised surface onto a piece of packaging, thereby bringing out a feel and depth. It emphasises patterns of logos or the names of brands with a sense of touch to which customers are attracted. This approach supports visual appeal to showcase superior quality.

Debossing

Debossing refers to an indentation made on the surface of the package, which is made using pressure. The finish is professional, gentle to the touch. It is regularly used by brands that want to portray subtle elegance. Debossing creates depth so that other features do not look overdone and the presentation looks sophisticated.

Die Cut Windows

Die-cut windows provide visibility to the product inside the box without opening it. The transparent window enhances credibility and creates attractiveness since customers can see the real product inside the box. The windows can also be shaped creatively in the observance of the branding theme, and make the shelf attractive.

Ribbons

Ribbons are ornaments on the packaging used to give a feel of beauty and elegance. They facilitate ease in unboxing and add an escalated gifting experience. Companies employ the use of ribbons in order to create glam and high-end branding. They are flexible enough to be used as luxury apparel to cosmetics, confectionery and celebratory product displays.

Strings

The use of Strings can be decorative and practical in the package’s design. They add functionality and also aesthetic values that improve the process of unboxing. These are ideal in pouches, gift bags and custom boxes where both practical use and aesthetics are desirable.

Tear Notch

A tear notch is a tear-open technology where a small piece of the packaging is cut lightly towards the customer in order to open the packaging easily. It makes it convenient without breaking the product inside. Tear notches can be found in food and pharmaceutical packaging. They do not require scissors to access the product, and keep the products well-protected.

Custom Inserts

Custom inserts lock products within the packaging by keeping the items in position as they go through transit. Inserts are custom-fit to particular products to increase safety. Inserts are also more presentable since they show products in a well-organised manner, which increases the quality of unboxing and customer satisfaction.

Our Exclusive Range Of Packaging

We have an extensive range of custom packaging bags. Whether you want to get custom boxes for your retail brand or you are looking for cupcake boxes for your bakery, we have got you covered. Our packaging boxes are available for all industries, such as:

Apparel Boxes

Custom Apparel Boxes are chic and fashionable protective elements in which clothes are displayed and are used to enhance your brand display. They preserve garments against dust, moisture, and pressure folds. Apparel boxes can be customised with high-quality prints, interior effects such as inserts, eco-friendly packaging materials, and more. All to ensure their customers receive their goods in the neatest possible form.

Bakery Boxes

Bakery boxes are made to maintain the freshness, texture, and aroma of baked goods. They contain no contaminants, ensure product integrity in the course of transportation, and, with PVC windows, provide visibility. Custom bakery boxes are ideal because they offer space where one can print branding, nutritional information, and attractive designs to create a bakery that people will admire.

Custom Food Boxes

Food packaging refers to the mixture of utility and marketing in order to wrap up foodstuffs to eliminate the effects of heat, moisture, and contamination. It makes it compliant with food safety regulations and increases the shelf appeal. Customised designs, sustainably sourced materials, resealable, and many more add-ons increase the convenience of the customers, enhance their experience with the brand, and make the brand more credible in the competitive food market.

Customised Electronic Boxes

Custom electronic packaging provides more robust protection to delicate electronics against static, impact, and environmental stresses. Several options add to security, such as:

- Anti-shock inserts

- Conductive material

- Tamper-proof closures.

Custom printing and the use of eco-friendly materials will enhance the brand. This packaging contributes to secure delivery and specifies innovativeness with reliability and professionalism in the electronics market.

Retail Boxes

Product protection and attractiveness are combined by the use of retail boxes that persuade people to buy products. They are flexible, can be custom-made in terms of shape, size, and finishing, and used in luxury as well as in consumer products. Durable, strong construction creates lasting value. Custom printing and finishing options are available to create a striking presence that stimulates brand awareness and sales.

Custom Paper

Custom papers are used to suit packaging, wrapping of products, and advertising packages. They also have speciality papers, which are either coated or finished to be used in a sustainable environment. Custom wrapping paper is used frequently in the food and packaging industry. There are several types of paper that are moisture and grease-resistant, and some can tolerate high temperatures.

Mylar Bags

Mylar Bags are barrier pack varieties that maintain goodness and increase shelf life. They are water-resistant, light, and oxygen proof and have robust puncture resistance. Mylar bags and pouches are preferred by brands when it comes to food, pharmaceuticals, and electronics. Custom printing options enable businesses to print the branding and product information to build customer trust.

Book Your Order Now!

For custom boxes near me, visit our website and get the most luxurious packaging experience. Custom Boxes Market UK is one of the renowned packaging companies that gives wholesale rates and free shipping. Book your order now and enhance your sales in one go.

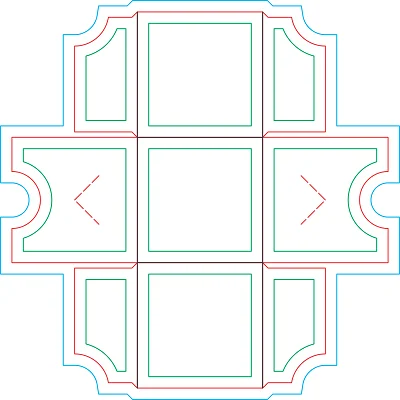

Artwork Preparation Guide

Preparing artwork for various purposes, whether it's for print, digital media, or other applications, requires attention to detail and adherence to specific guidelines. Here is a general artwork preparation guide that you can follow:

Cutting Line (Red Lines):

The red lines indicate the final size of the cuts. Important artwork, such as the logo and tagline of your brand, is kept 0.125 inches inside of the cutting line to avoid cutting.

Bleed Area (Blue Lines)

The bleed area indicates where the blue lines are located. It denotes the extra space beyond the final trim size of the design. This area makes sure that when the final box die line is cut, no white area remains.

Safe Area (Green Lines):

Safe area indicates the space where you can safely print the essential artwork element. The design content is kept in this margin to ensure a professional and seamless design.

Perforation Lines (Red Lines)

Perforation lines consist of the part of a paper that is punched to create dotted lines. The purpose of these lines is to ensure easy tearing or separation along the line.

Creasing Line (Black Lines)

Crease lines indicate the area where the box is to be folded.

01

Choose Your Box

Visit our website and see our inventory of BX styles. Select the option that goes well with your product, or if you do not have an idea about a suitable option, contact our customer care department and choose a viable option.

02

Customize the Design

After the selection of the box style, you can now upload your design in our design online tool or directly collaborate without designers to decorate the boxes with the custom options of your brand.

03

Select Materials and Finishes

Now you can select the material and finishing option for the boxes. We have diverse options and premium materials so that you can create boxes with lasting impressions. From tactile add-ons to glossy post-printing coating, choose all the aspects as you desire.

04

Review and Approve

Before we move to production, we'll send you a digital proof or a physical sample upon request. This ensures you're 100% satisfied with the design and materials chosen. Review, make any necessary changes, and give us the green light when you're ready.

05

Production Begins

If you finalise the quality and design, we will send your order to the production department, where we use one of the highest quality and advanced manufacturing facilities that give impeccable design with perfect quality. Each box is manufactured under careful quality control to avoid any errors.

06

Shipment and Delivery

Our company has partnered with one of the best logistics companies so that you can get your order on time. During the packing and shipment of the boxes, we will give you a tracking number so that you can check on the details of the delivery.

Cardboard

Corrugated

Kraft

Rigid

Anti Scratch Lamination

Aqueous Coating

Lamination

Silk Lamination Cards

Soft Touch Coating

Spot UV

Gloss Lamination

Gloss Varnish

Matt Lamination

Matt Varnish

Debossing

Embossing

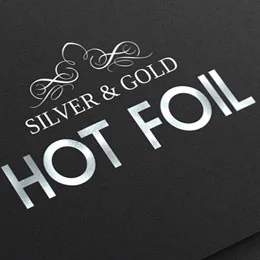

Foil stamping

Window Patching

Customer Support At Your Service

Do you have any questions about investing in our brand? Do you have any doubts about our custom box services? If yes, then our customer care representatives are ready to help. Our team of experts works around the clock to answer your questions instantly. You just need to fill in the form on our site, contact us through email or call us at the number given.

Get a Quote Call Us !

Get a Quote

Need Help?

Our team is here to assist you with any questions or concerns you may have. Whether you need guidance on product selection, design assistance, or order inquiries, we're just a click away.

Call Us NowFrequently Asked Questions

Do You Provide Us With A Free Mock-Up Design In The UK?

Yes, we offer a free-of-cost 3D mockup design to our client brands according to your desired design preference.

How Much Time You Take For Deliver Custom Boxes To My Location?

At PCB, we provide the fastest turnaround time in the market. You can received your custom boxes within 6-15 business days depending on the work required on your custom boxes. It also depends on your shipping location and size of your order. If you need quick delivery to your location, we have another pricing plan for that type of order.

How Can I Design Product Boxes As Per My Design Preference?

You can easily design your own boxes digitally using our online design tool. It is convenient to use and you can share the design with us after creating your box design and choosing the suitable material. Our team of experts analyse your design and creates custom boxes as per your design ideas. That you can create captivating and professional boxes for your brand.

What Custom Box Embellishments You Offer To Your Clients

We design your product boxes using a large variety of finishes and additional features to make your custom boxes look appealing to others. These feature protect the product from moisture and dust, and enhance the functionality of the packaging boxes.

What Custom Box Embellishments You Offer To Your Clients

We design your product boxes using a large variety of finishes and additional features to make your custom boxes look appealing to others. These feature protect the product from moisture and dust, and enhance the functionality of the packaging boxes.

Consequently, these finishes are Glossy Lamination, Matte Lamination, Vanish Coat, Spot UV, Blind Embossing, Blind Debossing, Hot Stamp Foiling, and others. You also can add handles, hanging tabs, transparent widnows, and insert to the product box to make them handy to customers.

Do You Charge Any Fee For Shipping My Packaging Boxes In The UK?

No, we don’t charge any money for shipping your custom boxes in the United States. It make us the best packaging partner for your brand in the packaging market.